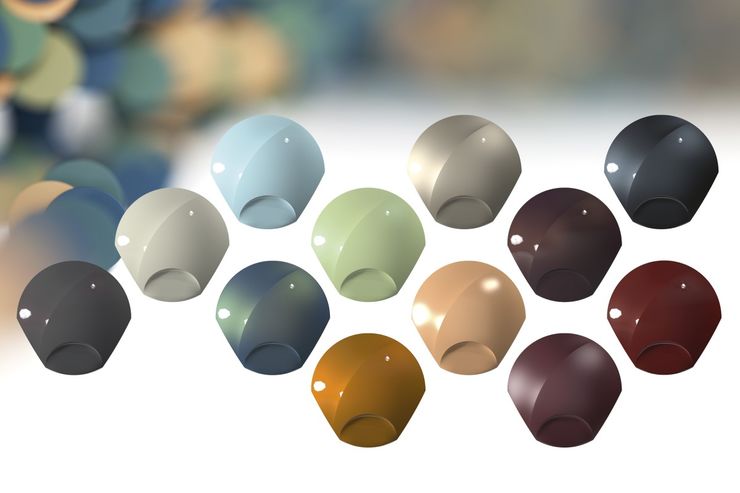

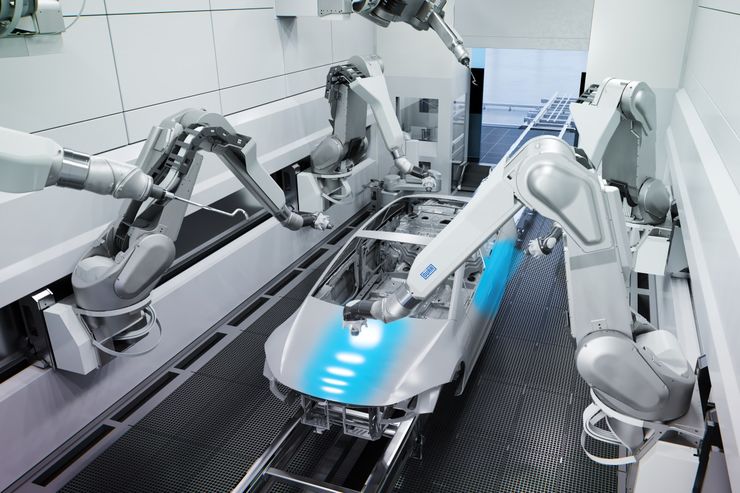

BASF's Color Brite Airspace Blue Re Source basecoat, certified by REDcert² according to a biomass balance approach, is making its debut in the Chinese market. This is the first time that biomass-balanced OEM coatings from BASF have been introduced in Asia since their official launch in Europe in May this year. The first batch went to a customer in China. The basecoat enables a reduction of the CO2 footprint by about 20%. The level of savings is verified by an independent sustainability consultant. BASF also received biomass balance certification for its resin plant in Caojing and for its coatings production sites in Minhang and Caojing, which are operated by BASF Shanghai Coatings Co., Ltd. This certification enables BASF to offer its customers in China a comprehensive range of biomass-balanced automotive coatings using materials from renewable resources. "Replacing fossil raw materials with renewable raw materials through BASF's biomass balance approach illustrates our promise to help our customers achieve their CO2 emission targets while maintaining high product quality and performance. The certification of our sites in China for the biomass balance approach underscores our commitment as an industry leader in promoting sustainability and innovation. We look forward to working with more automotive manufacturers in China and contributing together to a resource-efficient and carbon-neutral future," said Jack Zou, vice president, Automotive OEM Coatings Solutions Asia Pacific, BASF. In BASF's biomass balance approach, renewable raw materials are already used in the production of basic chemical products. The proportion of renewable raw materials is then mathematically allocated to specific sales products using a certified mass balance method. REDcert² is a certification system for the sustainable use of biomass that confirms that BASF has replaced the quantities of fossil resources required for the biomass-balanced product sold with renewable raw materials.

Autor(en): wi