BASF has calculated the individual carbon footprints for a large proportion of its chemical intermediates. The results were compared with assessments of the market-wide average Product Carbon Footprints (PCFs) of the corresponding products manufactured by third-party suppliers. The result of the analysis shows that the PCF of several of BASF's chemical intermediates is significantly lower than the global average PCF of the corresponding third-party products, considering production from fossil raw materials in each case. The PCF comprises the total greenhouse gas emissions generated: From raw material extraction to the production of precursors to the manufacture of the final product. On the way to its goal of achieving net zero CO2 emissions by 2050, BASF is the first major chemical company to calculate the individual carbon footprints of all its sales products. BASF now offers these products as "low-PCF" intermediates. These include tert-butylamine (tBA), formic acid, propionic acid, 1,6-hexanediol (HDO) and neopentyl glycol (NPG).

Several factors contribute to low carbon footprint

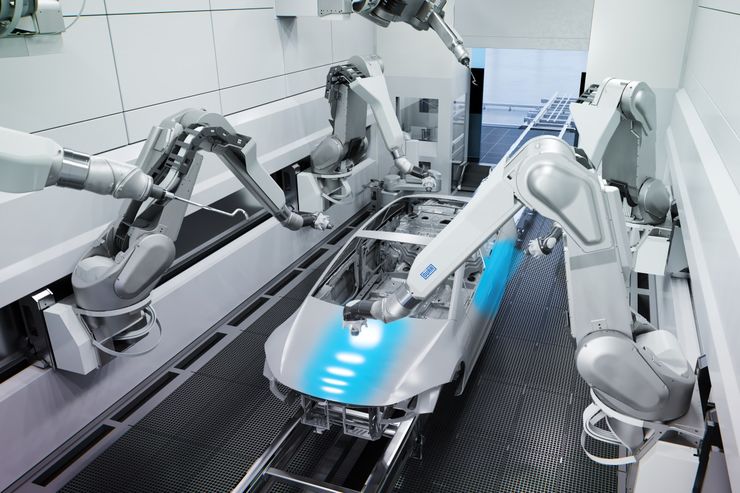

The PCF is influenced by several factors. For example, energy production in BASF's own gas-fired combined heat and power plants causes significantly lower greenhouse gas emissions than other, conventional forms of energy production. In addition, the production processes of low-PCF intermediates are characterised by high efficiency in terms of energy and raw material consumption, which is due to the integrated Verbund system and continuous operational excellence activities. In addition, low-PCF intermediates usually use oil, natural gas or composite by-products as primary raw materials, but not coal. Due to its chemical properties, the use of coal generally leads to a higher carbon footprint of downstream products compared to natural gas or oil. The aforementioned low-PCF intermediates are versatile chemicals that are used as ingredients in many everyday products. Examples include plastics, car tyres, de-icing agents, pharmaceuticals, crop protection products, paints and coatings. BASF customers use them in the textile, automotive, agricultural, pharmaceutical and furniture industries, among others.

Autor(en): wi