The 34th Control - international trade fair for quality assurance (QA) - took place from 3 through 6 May 2022, with great success according to promoter P. E. Schall. 18,531 expert visitors finally experienced QA advancements from the fields of vision technology, image processing, sensor technology, as well as measuring and testing technology - live and present - again after the two-year break in Stuttgart due to the pandemic. 617 exhibitors showed solution innovations and efficient QS cutting-edge technologies on almost 23,000 m2 of floor space in six halls. "It's great that we can exhibit at Control again after two years without," said Gerhard Mohr, Managing Director of Kapp Niles Metrology GmbH in Großostheim. "It's gratifying to see that trade visitors are coming back, that the attendance fairs are picking up speed again and that we're getting a bit closer to the old reality." Matthias Ruf, Head of Sales at the SKZ Plastics Centre in Würzburg, was equally pleased. "For us, Control was successful from the very first day of the fair and attracted a great deal of interest from visitors," Ruf explained. "We are happy to be able to present ourselves here as SKZ in a professional way."

31 % of the exhibitors had travelled from abroad; 6 % of the exhibitors came from Switzerland, 4 % from Italy, 3 % from the USA, and a good 2 % of the exhibitors came from the UK. Fabian Krüger, Control project manager, expressly thanked every exhibitor, including the trade fair teams, for making the Control restart a reality. Bettina Schall, managing director of the trade fair promoter, also expressed her delight and satisfaction: "This trade fair was awaited with great anticipation, with excitement and with the best mood in the run-up. Because we all missed the personal exchange, the expert discussion at eye level, the real experience of the systems with all our senses. Fortunately, this is now possible again!

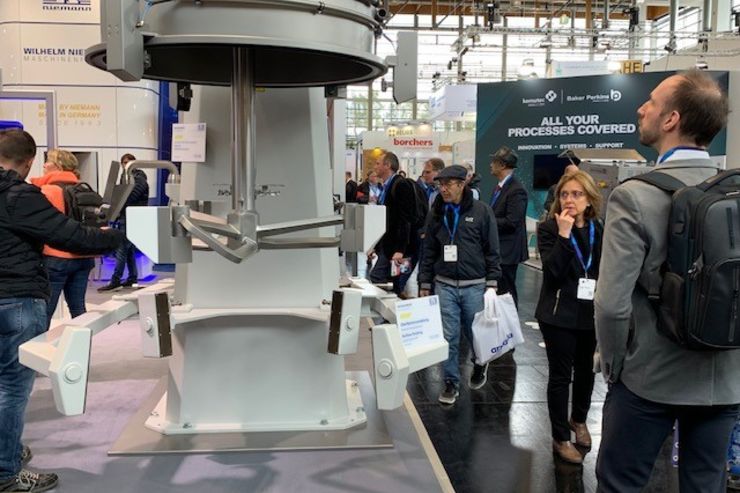

In all the halls, it was obvious that there is a huge demand for personal exchange about new developments. In the past three years since the last Control, quality inspection and quality assurance have taken on a new importance due to growing automation and digitalisation, contactless processes and remote services, small batch sizes, zero-defect manufacturing and data analyses. That is why news about measuring and testing technology, materials testing, analysis equipment, vision technology, image processing, sensor technology and weighing and counting technology were eagerly awaited. Above all, the use of artificial intelligence (AI) processes also met with great interest. The fact that AI has long since arrived in production and significantly simplifies QA processes could be experienced in many places. Even small industrial companies can realise a simple entry into AI support, as demonstrated for example by Dr. Dominik Lausch from Denkweit GmbH in Halle together with Marvin Krebs from Xactools in Bönnigheim. Measurement processes have to be increasingly fast, and they have to be more and more reliable. AI-supported methods support this. One of the current topics is that measuring, testing and inspection processes are an integral part of the manufacturing processes. Instead of taking place in specially created measuring environments, inspection processes are taking place in environments with dust and vibrations as well as under time pressure, which results in new challenges for measuring machines and inspection equipment. "We are increasingly working on this," confirmed Dr Heike Wenzel, Managing Partner of the Wenzel Group, who was also enthusiastic about finally being back live in Stuttgart.

Autor(en): mak