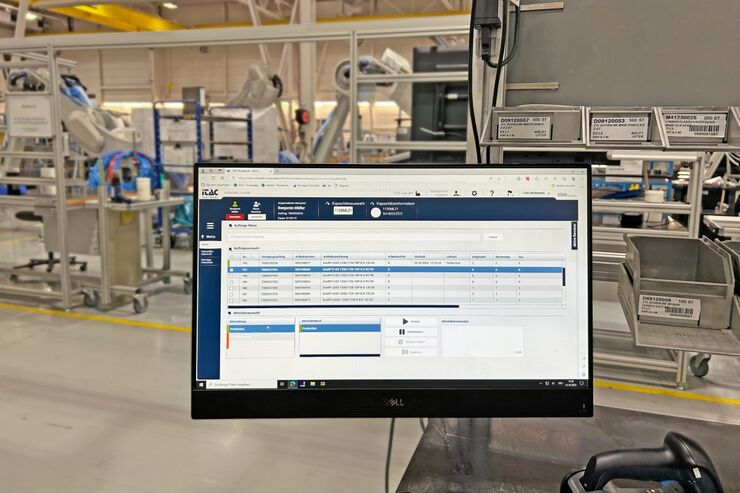

A Manufacturing Operations Management (MOM) system developed jointly by Dürr and its subsidiary iTAC is to map production digitally and in real time across all Group locations in future in line with the Group’s “OneMES strategy”. The system aims to standardize the IT landscape with as few interfaces as possible. The aim is to make production processes more efficient and optimize their planning and control.

The inhouse application is geared towards the requirements of mechanical engineering and is intended to serve as a best-practice reference for other mechanical engineering companies. Dr. Arndt Eigeldinger, Vice President Manufacturing & Logistics at Dürr, describes the system solution as a general blueprint for mechanical engineering. The focus is on the end-to-end networking of the store floor, from machine integration and data acquisition to order control and worker management through to optimized order planning and execution with corresponding transparency across all levels of production and assembly.

According to Dürr, the standardized MOM makes it possible, among other things, to analyze unplanned downtimes, continuously improve machine running times and define systematic shutdown measures. As Martin Heinz, CEO of iTAC Software AG, explains, the detailed planning of production and assembly as well as the integration of the quality department and logistics are also important features of the new system. For this reason, the new solution also includes the production planning software Ganttplan and the area planning software Areaplan from iTAC subsidiary Dualis.

Autor(en): spa