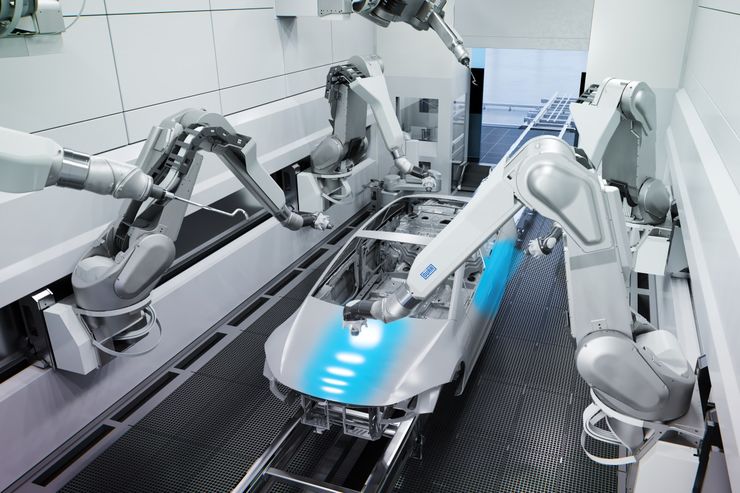

In the automotive industry, the variety of models is growing and with it the wide range in which individual plants have to produce. This demands greater flexibility in production in order to be able to cope with the ever-increasing demands of the future. Dürr has therefore developed the concept of the "paint shop of the future", which instead of the conventional rigid line relies on a visionary layout with flexible boxes. The innovative EcoProBooth paint booth is optimally matched to the box layout and combines up to three painting processes - the interior and the two exterior jobs - in just one booth. Up to eight painting robots, supported by four Scara robots for opening the doors, apply the paint to the bodywork - both inside and outside. This saves process time: firstly, two of the three conveyor processes previously used are no longer necessary, since the car bodies remain in the cabin and do not have to be conveyed from one cabin to the next between application processes. Secondly, the robots for exterior painting can be cleaned when they pause, while the remaining robots apply the interior painting - and vice versa. By distributing the tasks, different, optimally coordinated application techniques can be used for the exterior and interior painting in one booth, thus achieving the best possible quality.

The new painting cabin has so-called service cubicles: service cabins which are integrated in each corner of the painting cabin, are continuously flushed with fresh air and are accessible at all times without hesitation. If a robot has to be cleaned or maintained, it moves to the Service Cubicle and stretches its arm through a connecting window into the service area, where an employee can easily reach it. In doing so, the limit values for a workplace without health risks are observed. Up to now, production has had to be stopped at least every two to four hours in order to clean robots or carry out minor maintenance work. Now, atomisers can be cleaned or bell plates can be replaced during production without the responsible employee having to enter the application area in the spray booth. This significantly increases system availability.

Low energy consumption through maximum air circulation

In terms of the air recirculation rate, the spray booth goes to the maximum in order to minimise energy consumption and thus CO2 emissions. Whereas the ratio of circulating air to fresh air is 80:20 with a classic dry separation system, the ratio with EcoProBooth is 95:5. The spray booth is equipped as standard with a dry separation system (EcoDryScrubber) which ensures 100% paint separation, regardless of the paint materials or paint mixtures. Here, the air is first cleaned of paint particles and then reconditioned in a circulating air unit directly assigned to the spray booth. The energy required for reconditioning the circulating air is much lower than for conditioning the fresh air from outside, which generally differs more from the conditions inside the cabin, depending on the region and season. The maximum air recirculation rate thus keeps energy consumption and CO2 emissions for conditioning as low as possible. Compared to previous paint booths operated in recirculated air, the increased recirculated air rate saves 10 to 15 % energy and thus also CO2.

Highest flexibility with low material consumption

The painting booth shows its full strength in the modular box concept. It enables simple scaling according to changing quantities. Assuming a body mix of small cars to medium-sized SUVs, the cabin is designed for 12 jobs per hour. A higher capacity can be achieved with smaller vehicles or less painting effort. In order to adjust the system to a higher demand for higher quantities, several boxes are arranged parallel and next to each other. In contrast to a line layout, with a parallel arrangement a malfunction only affects the affected booth; production in the remaining booths can continue, which increases overall line availability. The size and layout of the box are standardised so that simple changeovers and extensions are possible without affecting production in other box sections. The box layout also reduces material consumption due to lower losses during colour changes. Dividing the line into shorter sections enables coating jobs to be distributed in such a way that colour changes are minimised. This saves coating and rinsing agent, thus reducing both costs and VOC emissions.

The complete article was published in German in the September issue of JOT.

Autor(en): Dürr