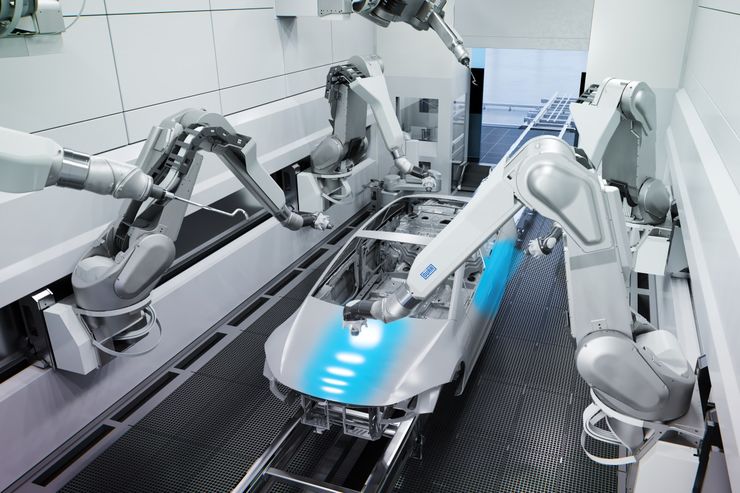

At Magna Steyr in Graz, six new models from four OEMs were integrated into the multi-OEM painting plant within three years. The spectrum ranges from classic off-road vehicles and sedans to convertibles and coupes in various substrates and all-electric versions. The paint shop has a capacity of 32.5 vehicles per hour, with an annual capacity of 165,000 to 190,000 vehicles depending on the shift model. Magna Steyr's paint shop has always had to be highly flexible in order to be able to integrate new models from different customers quickly and without major intervention in the production flow. For example, the Countryman and Paceman mini-models have already been painted in parallel together with Peugeot RCZ, Aston Martin Rapide and two models from another premium manufacturer. However, the current product range presented the plant with new challenges. New product generations require more or less intensive adaptations in almost all process steps of the paint shop, which can only be achieved by a consistent implementation of the strategy "As much as possible together, as much as necessary separately - specific requirements are solved with tailor-made processes" in plant engineering, technology and material and, above all, with the employees:

- Plant engineering: When integrating new plants as well as plant modifications, the focus is on a short integration time with low integration costs (flexibility), an economically reasonable degree of automation and sustainability.

- Technology and material: Essential for multi-OEM capability is a material strategy that meets the requirements of all OEMs. In addition, a contract manufacturer must be able to master and use new technologies at any time when the OEM raises them to a standard.

- Employees: The focus here is on qualifying employees to meet the different requirements of the products and training them in the corresponding skills.

Example: Integration of a new premium SUV

With the completely new development of a premium SUV, which has been manufactured by Magna Steyr in Graz since 1979, it became necessary, for example, to adapt the system technology without affecting the existing model, which continues to be built. Another challenge was the still very high level of premium quality, accompanied by a large number of variants (matt lacquer, variety of colours, special models). All processes are based on already implemented solutions for current and previous products of this OEM and were only adapted accordingly if necessary. In terms of system technology, the frameless body has been integrated into the underbody protection hanger, which, by installing additional roof mounts, continues to provide a 100 percent free underbody for optimum application. The hanger, which is already adjustable in four dimensions, can thus be extended by a further dimension with the roof mount. In terms of technology and material, a solution for matt painting in high production volumes has been implemented; to safeguard the distinctive sealing concept with a large number of paint stoppers, a fully automatic stopper control system using a camera system has been installed. With regard to employees, this model focuses on training for the high quality standard and the product differences between the two variants. An additional advantage is the perfected matt paint finish, which is now also available for other customers in the Magna Steyr paint shop.

The complete article was published in German in the May/June issue of JOT.

Autor(en): Dipl. -Ing. Philipp Rucker, Magna Steyr Fahrzeugtechnik