In 2017, the tech start-up Visometry specialized in augmented reality solutions (AR solutions) for industrial applications as a Fraunhofer spin-off. The company originated at the Fraunhofer Institute for Computer Graphics Research (IGD). Here, the founders researched innovative AR tracking methods for more than ten years and developed the basis of today's VisionLib engine for reliable and stable object recognition. Starting from the core technology, today a team of passionate XR developers and experienced business experts develops and markets image processing solutions for industrial AR applications. In doing so, its products focus on quality assurance in the manufacturing industry with the goal of significantly reducing inspection and follow-up costs. "Since our founding, we have made a name for ourselves as an innovative partner to industry with great expertise in AR and computer vision," explains CEO and co-founder Dr. Harald Wuest. "With our leading technologies, we support companies in their digital transformation, ensuring greater efficiency and quality while reducing costs. "The start-up's core product is the VisionLib engine, which forms the basis for a wide range of AR applications that require powerful object recognition and precise object tracking. Based on model-based tracking technologies, CAD data is registered in real time on objects captured in camera images. The special feature here is on the one hand the reliable object recognition even in low-light and dynamic environments, and on the other hand the accuracy that enables precise augmentation of CAD data. The VisionLib engine is now used by more than 250 customers worldwide, including Volkswagen, Daimler, Porsche, SAP and Siemens. It is used for AR apps and XR services in production, maintenance and quality assurance to increase productivity and ensure high quality with low inspection costs.

Turnkey solution for quality inspection

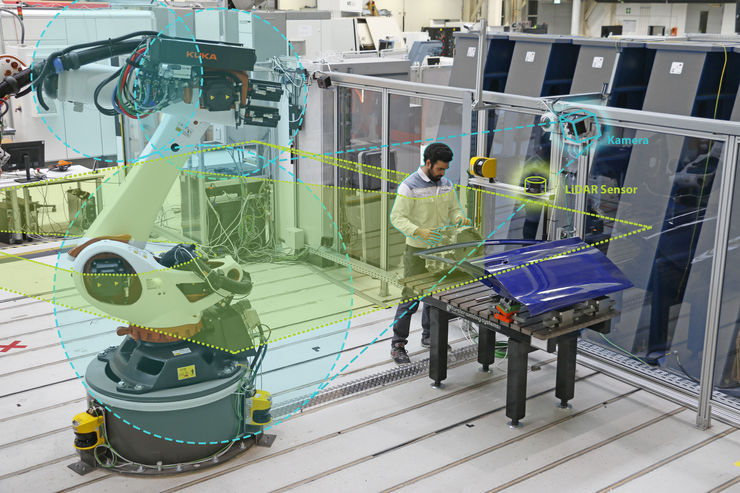

Visometry has also been offering Twyn, a turnkey solution for visual quality inspection, for two years. It is characterized by its high degree of innovation and simple operation via tablet: The mobile inspection system uses AR for a flexible and highly efficient quality inspection of components or entire assemblies. Through the camera of a tablet, Twyn automatically locates, registers and tracks inspection parts in real time directly where parts are produced or stored. Using CAD data and AR, a digital twin is then superimposed directly onto the object. Deviations between target and actual conditions thus become immediately visible. Twyn is used in a wide variety of areas and industries: These include incoming and outgoing goods inspection as well as construction condition control in mechanical engineering, plant engineering, automotive and aircraft construction as well as in agricultural machinery manufacturing. The system has received the "Top Innovation 2022" award from the trade journal inVISION, among others. At the Control trade fair in Stuttgart, trade fair visitors can test for themselves how simply and efficiently Twyn can support quality assurance.

Autor(en): wi