For the digitalisation and automation of modern production and logistics systems, every component, every semi-finished product and, in some cases, every raw material in the production process must be uniquely identifiable and traceable - at every stage of processing and across many instances. This creates transparency and allows all production-relevant decisions to be made at any time on the basis of unambiguous information. This benefits production and logistics processes on the one hand, and optimises quality, productivity and costs on the other. However, the conventional object markings usually used today, such as labels or barcodes, cannot usually remain permanently and undamaged on the object to be identified for production reasons. Other methods, such as determination by shape, colour or weight, or the detection of optical features on the object surface, do not guarantee complete identification and traceability. They are either only applicable to a limited extent or are susceptible as soon as the surface changes too much during a processing step or is deliberately manipulated.

Combining different methods for product identification

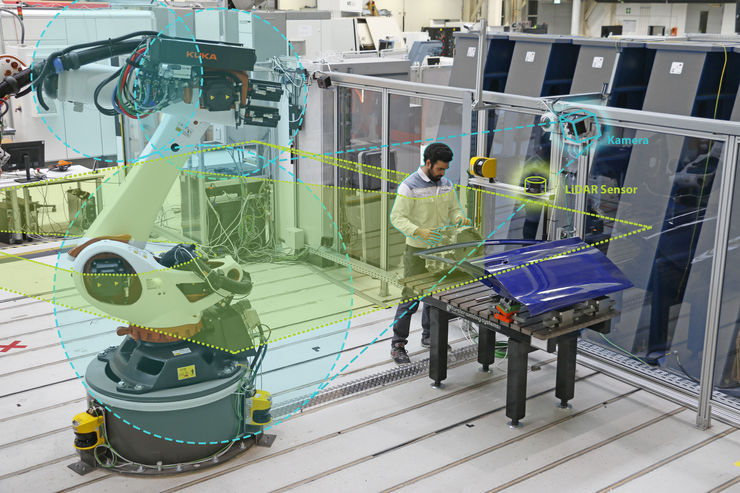

For this reason, the Fraunhofer Institute for Factory Operation and Automation IFF in Magdeburg is currently developing a new, universally applicable system for product and raw material identification that will be available for almost any application in production and logistics processes once it is completed. The new system combines various modern methods for product recognition, localisation and classification. Among other things, it relies on methods for non-destructive testing to determine unique features from inside the component. These features are not destroyed or concealed by subsequent processing steps and can be used for permanent identification as well as for protection against product plagiarism. The various technologies are supplemented and linked with regard to data processing with machine learning methods. This is to ensure that characteristic properties are preserved and that changing product properties and variations do not impair the unambiguous and robust recognition.

As a result, the future technology creates a kind of "virtual DNA" by combining any number of individual properties of an object, by means of which it can be identified unambiguously, long-term and at any time. As a core technology, the new identification technique should be adaptable to any application. Further advantages would be a significant cost saving, since the generation and attachment of artificial identifiers can be dispensed with, the possibility of identifying small parts or raw materials as well as increased counterfeit protection.

Once development is completed, the Fraunhofer IFF will make the technology available to companies in the manufacturing and service sectors in Saxony-Anhalt but also beyond the region without affecting competition. The project has a volume of about 400,000 euros and is being funded by the state of Saxony-Anhalt and the European Regional Development Fund (ERDF) with about 320,000 euros. The project runs from 1 August 2020 to 28 February 2022.

Autor(en): Wi