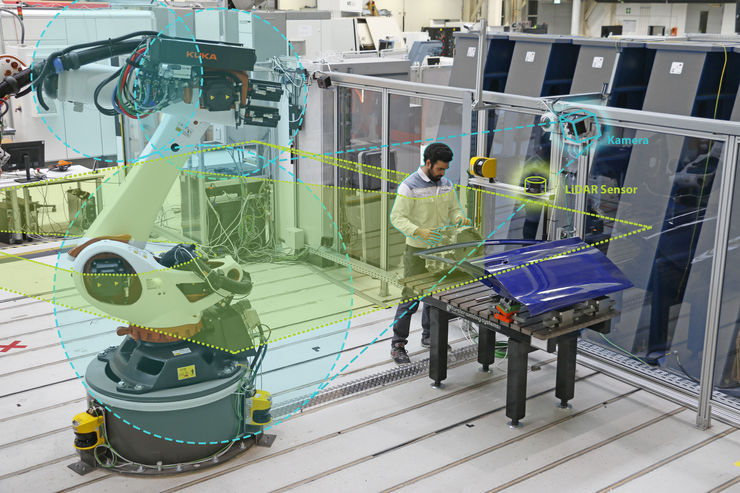

The mobility company Enovate integrates research and development, production, sales and service of battery electric vehicles. Its brand concept focuses on design, quality and intelligent connectivity. The company aims to rethink smart design and green mobility and implement its ideas with innovative technology. The first ME7 model has been officially available since last autumn. The new plant in Changsha, one of China‘s major cities, is designed for an initial annual capacity of 60,000 units and w scheduled to start production in 2021. Dürr built a scalable paint shop for the production site that can flexibly grow with increasing demand. To enable Enovate to expand its production in response to rising demand, Enovate opted to use automated guided vehicles (AGV) around its manual workstations. The AGVs are a flexible conveyor technology that is not restrained by cycle times and can be easily extended as production figures grow.

Investments according to real needs

Unlike conventional in-floor conveyor technology, more AGVs can be added as additional workstations are built. This is economically attractive, especially for newcomers to e-mobility; they can begin with small quantities and gradually expand as demand increases. Driverless transport vehicles offer the flexibility to postpone expansion until it becomes a requirement for the manufacturer.

The complete article was published in IST 03/2021.

Autor(en): Dürr Systems AG Bietigheim-Bissingen (Germany)