With the newly opened Center for Networked Surface and Paint Technology, Fraunhofer IFAM is researching the digital future of surface treatment through machine learning. On more than 750 m2 of pilot plant space with state-of-the-art equipment, the institute is pooling its expertise in the areas of cleaning, pre-treatment, painting and quality assurance for the automated processing of small and large structures. The central development goals here are fully automated process chains for robot-guided mobile and inline-capable applications for series use. The possibilities of automation and digitalisation are far from exhausted when it comes to control and quality assurance along the entire process. In order to gain a better understanding of the entire process and to drive developments forward safely and quickly, the experts at Fraunhofer IFAM are looking at the entire value and process chain from surface treatment to the painted component. The process chain is digitally mapped and supplemented with interaction options using virtual and augmented reality. Research and development goals include the realisation of digitally networked surface technology systems and processes as well as process and quality optimisation through machine learning and the use of AR/VR methods.

How virtual reality becomes reality in industrial practice

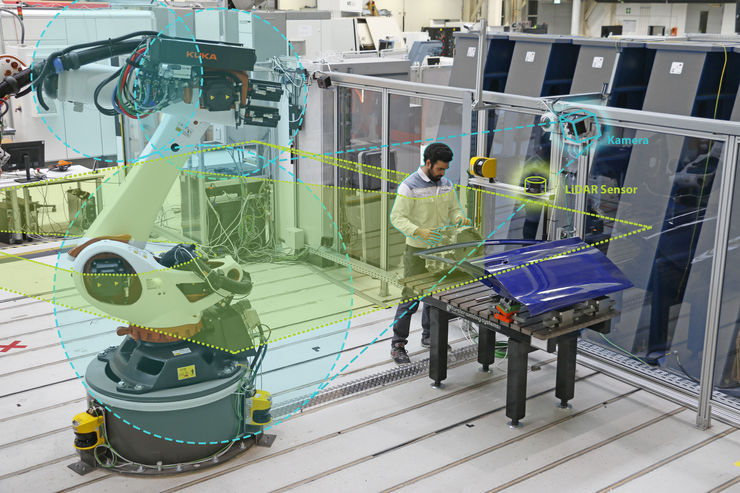

Virtual Reality, Augmented Reality, Internet-of-Things - digital tools and methods that link virtual models with real components are the forward-looking applications in surface treatment and painting processes. Implemented correctly, they offer enormous potential for product development, process efficiency and quality assurance. Current challenges are the storage and management of relevant data, a creation of reliable models and resilient simulations, the correct provision of data and continuous data flow along the entire process chain, an automated inclusion of relevant data to optimise process steps and the integration of interfaces for human-machine interactions. Industry representatives immediately recognise the advantages of digital tools and methods. However, integrating the technologies into one's own treatment and painting process is extremely complex. This is precisely where the new "Centre for Networked Surface and Paint Technology" comes in. With this holistic, application-oriented and practical offer for industry and research partners, processes can be selected according to requirements and optimised for individual production conditions. In addition, commercial coating processes can be simulated and optimised.

Development examples from practice

Pretreatment with plasma technology and decoating with laser techniques are precision processes for preparing the surfaces of components for further processing in the process chain, for example for bonding or painting. The slightest fluctuations in the process parameters or starting materials can have serious consequences, even leading to component failure. Surface pre-treatment processes must therefore be carried out in an extremely controlled manner. To counteract process fluctuations, Fraunhofer IFAM is researching into making these processes self-adjusting using optical and spectroscopic monitoring methods in combination with artificial intelligence and thus making them safer. One approach in particular is to control pre-treatment processes with self-learning algorithms. In the first step, characteristic emissions of these processes, actual values of the process parameters and the resulting product properties are recorded using inline-capable spectroscopic methods. For example, the use of a high-resolution hyperspectral camera is suitable for this. In a second step, these data will be linked with existing algorithms from the machine learning field as well as AI methods and correlations between these data will be learned. Based on the knowledge gained, it should be possible to reliably detect deviations in the process in real time and to initiate countermeasures in order to ultimately obtain a reproducible surface condition even with variable input variables, for example in the case of process instabilities or variable initial conditions.

The subsequent painting process and, above all, the result depends not only on the pre-treatment mentioned and the coating material, but also on the application technique selected. A wide variety of techniques, from pneumatic to airless to electrostatically assisted painting, are available on the market and often lead to different painting results, even when an identical coating material is used. One of the tasks of the centre's scientists will be to investigate the influence of the application technique on the painting result, in order to then use this knowledge to develop transferable prediction models. Among other things, a painting robot is available for these tasks, which is characterised by a reach of over 2600 mm and a payload of up to 45 kg, so that it can also be used for paint technology issues from the aerospace industry.

Digital solutions for mobile and inline applications are being developed for quality assurance in order to safeguard processes and quickly determine material and production data. The focus here is on the development of new measurement methods from laboratory applications to use under real conditions. In particular, non-contact spectroscopic methods in the short-wave infrared range and ultraviolet range are available here. By digitally mapping the entire value chain and implementing artificial intelligence, the respective process steps can be better understood and transferred into physical models. Process parameters could thus be set as required for different components and surface conditions, the interactions with subsequent process steps could be predicted and the desired coating result achieved.

Autor(en): wi